G04- Dwell Time:

It is used for stopping the tool movement for a specified time.

Commonly G04 is used to

Hold the axis movements until the chuck rotates in the given r.p.m.

Hold the axis movements until the coolant gets the required pressure.

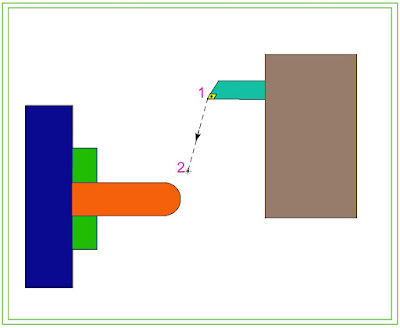

Getting a good surface finishing by allowing the tool to wait for a while before it goes to the next destination.

Ex:-

For 2 Seconds delay -

It is used for stopping the tool movement for a specified time.

Commonly G04 is used to

Hold the axis movements until the chuck rotates in the given r.p.m.

Hold the axis movements until the coolant gets the required pressure.

Getting a good surface finishing by allowing the tool to wait for a while before it goes to the next destination.

Ex:-

For 2 Seconds delay -

G04 X2.0;

or

G04 U2.0;

or

G04 P2000;